A MAGNET Internship at the Nu Instruments factory

By Anaïs Fourny and Genna Patton

It has been observed that one needs to match perfectly standard-sample concentrations to achieve good sample-standard bracketing precision on Δ56Fe/54Fe (‰) and Δ57Fe/54Fe (‰) when using dry plasma. The goal of our internship is to assess the performance of the Nu Plasma II multiple collector-inductively coupled plasma-mass spectrometer (MC-ICP-MS) for Fe isotopes, depending of the type of sample introduction and the concentration difference between samples and standards.

During the two weeks at the Nu Instruments factory (Wrexham, UK), we explored two introduction methods for Fe isotope analysis using two Fe standards: wet and dry plasma. In wet plasma, the sample in solution is directly introduced into the plasma, whereas in dry plasma mode, the sample in solution goes first through a membrane that removes the solvent.

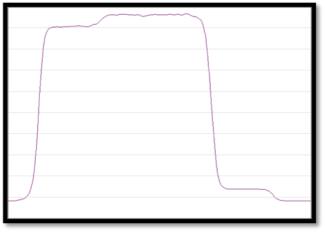

For all the experiments, we were analyzing in pseudo-high resolution: we were measuring the Fe isotopic ratios on the interference-free peak shoulder (Fig. 1). We checked the resolution before each experiment, so after the two weeks we got quite good at calculating resolution!

The first experiment was to run solution with different Fe concentrations on wet plasma to see when the mass bias occurred (Fig. 2). During this first test, we also looked at the difference in precision achieved using either blank subtraction (after each wash a blank is measured) or ESA deflection (average blank measurement on the peak at the beginning of analysis). Based on the results, the other experiments were conducted using blank subtraction.

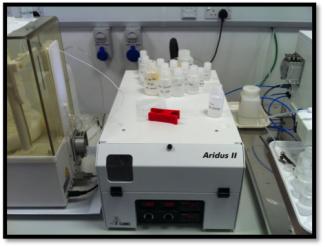

During the second experiment, we tested the effect of concentration differences when using an Apex Q (still wet mode but with a bigger spray chamber; Fig. 3). Then, we looked into their effect when samples went through an Aridus II (dry plasma; Fig. 4). Finally, we examined the mass bias using an Aridus II, followed by addition of solvent before introduction into the plasma.

Because we were working intensely on the Nu Plasma II, using a variety of sample introduction methods, there were several adjustments that needed to be made to the instrument over the course of the two weeks. For example, we had the opportunity to change the sampler cone and skimmer cone, depending on whether we were running the instrument in wet or dry mode.

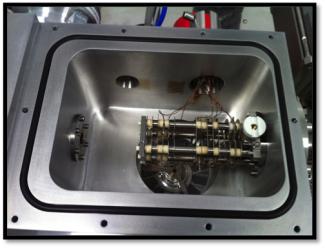

Measuring Fe requires the high-resolution (HR) slit to resolve the interference-free shoulder of the Fe peak. The HR slit removes around 75% of the ion beam; however, this slit will slowly increase in width with regular use. Therefore, routine maintenance includes changing the HR slit. We observed how the Nu Instruments technicians removed the transfer lens assembly, changed the HR slit, and pumped down the transfer lens chamber afterward (Fig. 5). The measurements we were making lent themselves to these changing instrument configurations and because of this, we learned a lot about the internal workings of the instrument!

Given our limited time at the factory, it was necessary to run overnight in addition to during the day, so we relied quite a bit on autosamplers during the night. On multiple mornings, we arrived to find that the autosampler had malfunctioned, which taught us an important lesson: the instruments are much more reliable than the autosamplers.

During daytime runs we had the opportunity to talk with applications scientists and engineers working on the other instruments at Nu, including the TIMS, the Astrum, the Noblesse and the Panorama. Many different sample types can be measured on the amazing range of instruments available, from the Astrum, a solid state elemental analyzer, to the Noblesse, a noble gas analyzer that can measure samples as small as 106 atoms.

The Panorama is a giant instrument that will be capable of measuring isotopologues of gases like methane that require extremely high resolution and high sensitivity. We saw the new TIMS instrument that is being manufactured and talked with the applications scientist who is working with it. This TIMS instrument has fixed detectors, which require zoom optics patented by Nu.

After two weeks of being totally immersed in the Nu factory, we felt as though we had attended a mass spectrometry summer camp. We had a fantastic time and learned so much from all the incredible scientists and engineers who work there!

About MAGNET

The Multidisciplinary Applied Geochemistry Network, or MAGNET, is an NSERC-funded industrial-stream Collaborative Research and Training Experience (CREATE) initiative devoted to geochemistry. Students receive hands-on and real-world experience in instrumentation, analysis and data interpretation.

About Nu Instruments

Nu Instruments, headquartered in Wrexham, UK, designs and manufactures high-performance mass spectrometers. Nu instruments is an official industry partner of the MAGNET program.